416r stainless steel charpy impact test|stainless steel impact testing : maker The INL developed a drop-weight impact testing machine (ITM) to begin the consideration of these variables and determine strain rate elevated true stress-strain curves for stainless steel . Hercai: Amor e Vingança é uma história que mistura paixão ardente e o desejo profundo de vingança, criando um enredo repleto de reviravoltas emocionantes. Com sua trama .

{plog:ftitle_list}

Fluente em Libras e ex-empresária no ramo de gráfica, restaurantes e casas de shows, Mia Linz relata em seu blog pessoal tudo o que . Ver mais

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load .The INL developed a drop-weight impact testing machine (ITM) to begin the consideration of these variables and determine strain rate elevated true stress-strain curves for stainless steel .

of Charpy reference specimens (4340 quenched and tempered with two energy levels, and T200 18Ni maraging steel). For each of the steels, tests were performed on standard E23 Charpy .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy impact test provides characteristic values for the impact strength at high strain rates in the form of a surface area related value. The test measures the impact energy in relation to the fracture surface in joules. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a .

416 is the most machinable grade of stainless steel. It is a low cost grade and can be used unhardened, hardened and highly tempered states. Hardness is optimised at the expense of other properties and corrosion .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .Since fracture or failure behavior depends on temperature, Charpy impact tests are often performed in the entire operating temperature range. This shows at what temperature and to what extent the material becomes brittle (tough-to-brittle .Temperature is the one parameters effect used and presented in the. The temperature effect between 20°C and 600°C was made for an austenitic stainless steel 316L under a specified environment [6]. The aim of this work . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .

For example, as auto parts or structural parts, they will undergo the impact fracture in service, which raises higher demands on the excellent impact toughness of stainless steel. Then, the impact . 316L stainless steel is a promising material candidate for a hydrogen containment system. However, when in contact with hydrogen, the material could be degraded by hydrogen embrittlement (HE). Moreover, the mechanism and the effect of HE on 316L stainless steel have not been clearly studied. This study investigated the effect of hydrogen exposure . the CVN impact test for the 12 h, 24 h and 48 h hydrogen charged and uncharged 316L stainless steel at 25 C (ambient temperature), − 50 C, − 125 C and − 196 C, respectively .impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of .

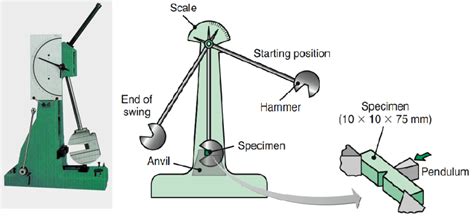

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .

undersized charpy impact test

stainless steel impact testing machine

Charpy impact test. The charpy impact and toughness properties of the tow-welded joint prepared with type ER316LN and ER308LN austenitic stainless steel filler metals have been compared. The results obtained have shown that the charpy impact energy of the weld is sensitive to the filler metal.

It has the highest machinability of any stainless steel at about 85% of that of a free-machining carbon steel. Martensitic stainless steels were designed to be hardenable by heat treatment and also corrosion resistant. Although Alloy 416 and other martensitic stainless steels are not as resistant as austenitic or ferritic stainless, it still .

416 is the most machinable grade of stainless steel. It is a low cost grade and can be used unhardened, hardened and highly tempered states. . Impact Charpy V (J) Annealed * 517. 275. 30. 262-Condition T ** 758. 586. 18. 248-302-204. 1340. 1050. 11. 388. 20. 316. 1350. 1060. 12. 388. 22. 427. . # Tempering of this steel at temperatures of .

impact testing machine the charpy ‘V’- notch impact test was carried out for weld metal. Gas tungsten arc welded joints using duplex stainless steel filler metal has higher charpy impact toughness values compared with the gas tungsten arc welded joints using austenitic stainless steel filler metals. The toughness value of

As duplex stainless steels contain both austenitic and ferritic microstructures, their impact toughness is limited by the presence of the ferritic microstructure. The ductile-to-brittle transition temperature is approximately –50°C. Testing Impact Toughness. The most widely used test of impact toughness is the Charpy test. There have also been studies on the effect of the microstructure on the impact toughness. An increase in the nitrogen content enhances the room temperature toughness of duplex stainless steels, which was ascribed to an increase in the austenite content and a decrease in the amount of nitrides [18].Karlsson et al. [19] showed that in a lean duplex .Up to a Charpy impact energy of 100J, the corresponding lateral expansion can be approximated by: LE(mm) = Charpy energy (J)/100. For higher Charpy energies, a fit to the data is given in Fig.1. References. C S Wiesner, . In this study, an austenitic stainless steel pipe for the transportation of liquefied natural gas (LNG) was gas tungsten arc welded with a wall thickness of 15.1 mm. Low-temperature Charpy V-notch .

Abstract In the framework of a collaborative project between ASME, NASA, and NIST, instrumented Charpy tests have been performed at liquid nitrogen temperature (77 K, or 196 °C) on specimens extracted from the center of four 316L welded stainless steel plates, each produced by a different vendor. deposits shall be impact tested in accordance with para. 323.3. • When impact testing is required by Table 323.2.2, paragraph 323.3.4 and sub-paragraphs require Charpy impact testing at a temperature not higher than the design minimum temperature. Note: Section VIII Division 1, UHA -51(a)(3) only requires impact testing at - 320°F

The most common materials used in cryogenic pressure piping are austenitic stainless steel (304/304L and 316/316L) and aluminum. . Charpy Impact test base metal and production weld samples at –320F. Unless the ratio of allowable to design stress is less than 0.35, in which case Impact Test (Toughness Test) is not required. .CRUCIBLE 416R: CRUCIBLE 416R is a hardenable chromium stainless steel particularly suited for use in high quality precision rifle barrels. This grade has good machinability and, because of closely controlled chemistry and processing techniques, may be machined and lapped to a high finish, which is important for bore accuracy. Charpy impact testing was performed using a Tinius Olsen model 74 universal impact tester under RT (~293 K) and LNT (~77 K). . This study systematically studied the crystallographic-orientation-dependent Charpy impact behaviours of stainless steel 316 L (SS316L) fabricated by laser powder bed fusion (LPBF) at room temperature (RT) and liquid .

Download scientific diagram | Charpy impact test criteria for 316 L(N) stainless steel: originally based (RCC-MR Code) on Charpy U specimen tests, but from now on Charpy V specimen. from . 416 stainless steel and 416R are both excellent choices for stainless steel applications. However, if high strength and durability are a primary concern, 416R is the best choice, while 416 stainless steel suits less demanding situations. Although 416R may be more expensive, it is worth the investment if your firearm will be subject to harsh .2.3 Charpy Impact Test The specimens for the Charpy Impact Test are prepared as per the ASTM standard E23-72 [11] and the specimen geometry is shown in Fig.4 Fig.4. Impact Test Specimen Geometry. The Impact test is carried out on Impact Testing Machine at room temperature for both the Cryogenic treated and untreated specimen and the results thus

The fifth edition of the Steel Castings Handbook (published by the Steel Founders' Society of America) includes a graph of Charpy V-notch toughness vs. temperature for CF8 (cast Type 304).The graph indicates the impact energy gradually declines from 125-215 ft-lbs [170-292 J] at ambient temperature down to 37-70 ft-lbs [50-95 J] at -325° F [-198° C].Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

stainless steel impact testing

notched charpy impact test

Tons of Creampie Eating porn tube videos and much more. This is the only porn resource you'll ever need!

416r stainless steel charpy impact test|stainless steel impact testing